- HOME

- Technology

- Slit

Slit

Slitted products are used for…

Our slitted products are used in a variety of everyday situations.

- Capacitor films of all types, including home appliances, PCs, and hybrid cars

- Computer backup tape

- Ultra-thin electromagnetic wave shield wire

- Optical liquid crystal display reflecting film

- Carrier tape

What will be demanded of slitted products in the future

Many different products use the slitter, and we also respond to a diversity of requests.

- Product quality

- Width accuracy

- Winding form

- Larger diameters

- Processes adding value to existing film

Our broad based response allows us to select the model best suited to the wide-ranging demands of our users, in fields as varied as electronics, information, electrical equipment, and healthcare.

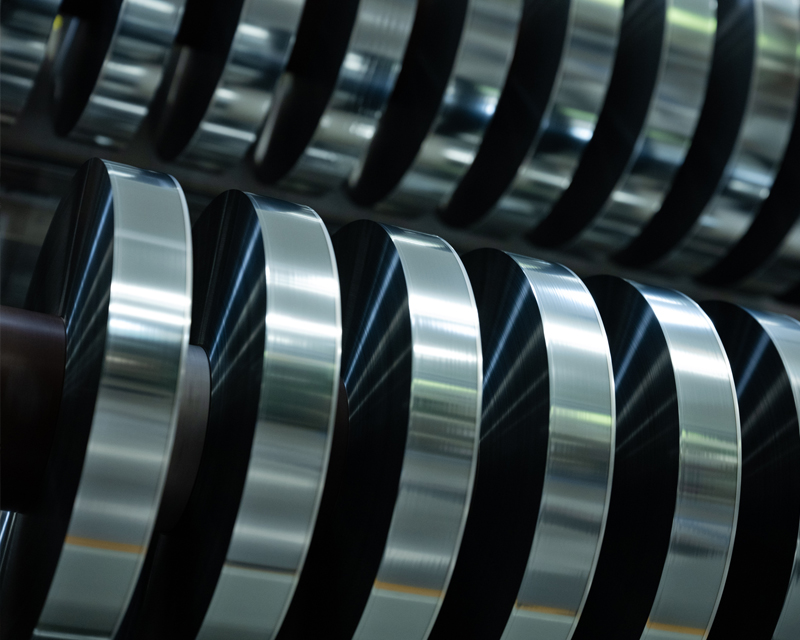

Slit process

We have 17 slitting machines.

Our advanced slitting technology meets the needs of our customers.

Microslitting machines

1. Uses

Capacitor film, release film, compound film, insulation film, magnetic tape, carrier tape

2. Characteristics

We have demonstrated our successful performance in accuracy and quality control by

achieving a slit process for optional narrow widths (as narrow as 3.5 mm) for

ultra-thin film.

The micro-slit is the achievement of which we are the most proud in our company’s

history.

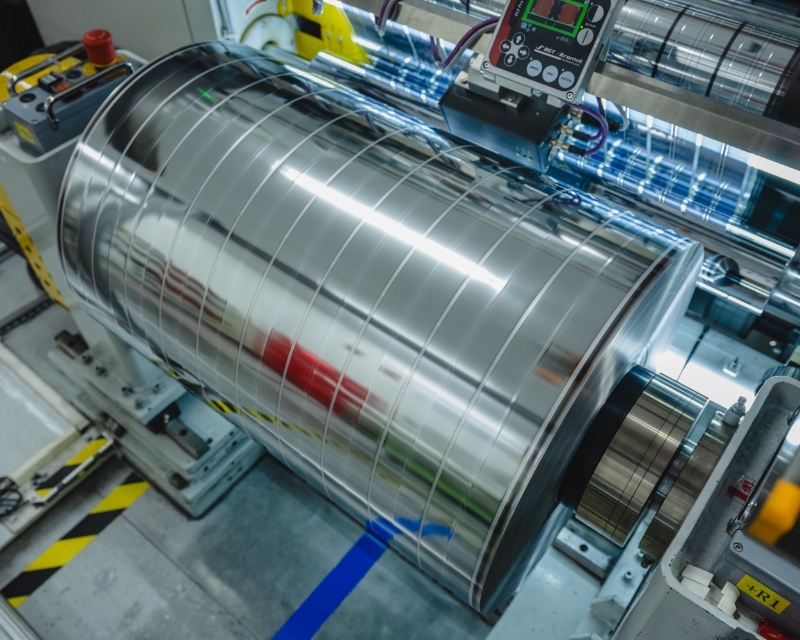

Large slitting machines

1. Uses

Optical and reflecting film, release film, packaging film, carrier film for all types of processes

2. Characteristics

We are capable of conducting the slit process in the clean room, and conducting the

corona E process at the same time.

We can process up to one ton of Ø1,000 material.

Traverse slitting machines

1. Uses

Insulation film, carrier film for all types of processes

2. Characteristics

We are capable of slitting traverse winding on ultra-narrow film (minimum width: 0.6

mm).

We also use a trapezoidal winding to prevent tape slackening, and can handle a

maximum winding length of 20,000 m.

Other slitting machine

We have large slitting machine capable of corona processing in a Class 3000 environment to meet any customer requirement for cleanliness.

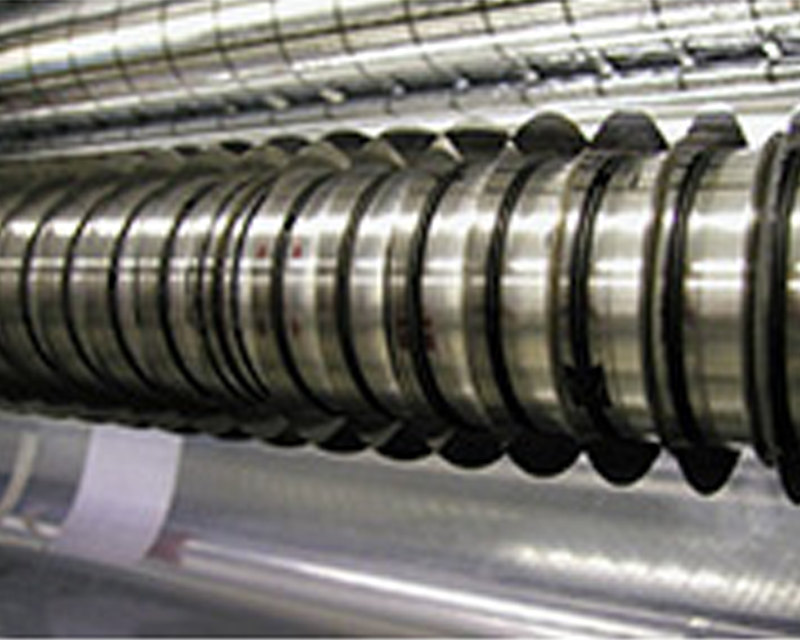

Slit process (Blade)

We use the share cut method.

We guarantee width accuracy that cannot be obtained with the laser cut method.

We grind all our blades in house to handle any type of film slits.

Blades for slitting

We grind our blades, the critical factor for slits, in house.

There is no device that can perform a satisfactory finishing and inspection. That’s

why the processes from the finish grinding to the tooth tip for each individual item

are done by hand.